What is Transformer ?

A transformer is a passive electrical device that uses electromagnetic induction to transmit electrical energy from one circuit to another. It is widely used to raise (‘step up’) or lower (‘step down’) voltage levels between circuits.

Working Principle of Transformer –

A transformer operates on the mutual induction principle. Mutual induction is the phenomena in which an E.M.F. is induced in an adjacent coil when the quantity of magnetic flux coupled with a coil varies.

The working principle of a transformer is based on Faraday’s Law of Mutual Induction, which occurs between two circuits connected by a mutual magnetic flux. Before we go into the operation of a transformer, let’s first look into the process of electromagnetic induction.

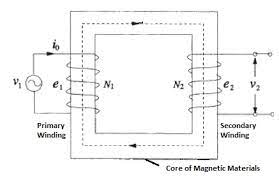

Construction :-

A rectangular iron core is the basic building block of a transformer. There are two coils: a primary coil (P) with two sides (P1 and P2) and a secondary coil (S) with two sides (S1 and S2). The ferro-magnetic iron core is isolated from each of these coils. The main winding serves as the alternate current’s source, while the secondary winding, which is coupled in parallel to a resistance R, provides the alternate current’s output.

- Input Connections – The principal side of a transformer is the input side since this is where the main electrical power to be altered is attached.

- Output Connections – The electrical power is transferred to the load through the transformer’s output side, also known as the secondary side. The incoming electric power is raised or lowered depending on the load’s requirements.

- Winding – Transformers have two windings, the main and secondary windings. The coil that receives electricity from the source is known as the primary winding. The secondary winding is the coil that distributes energy to the load at the converted or modified voltage. Typically, these two coils are separated into many coils to limit flux generation.

- Core :The transformer core serves as a regulated channel for the magnetic flux generated by the transformer. The core is typically not a solid steel bar, but rather a composite of several thin laminated steel sheets or layers. This design aids in the elimination and reduction of heating.

Transformer Components

A typical transformer is made up of the following major components:

Magnetic Core

The transformer’s core is constructed of magnetic materials with a high magnetic permeability. The transformer’s core is made of thin lamination stacked together since it is exposed to an AC supply, which lowers eddy current losses in the core. Transformer windings are looped around the core of the transformer. The transformer’s core primarily performs two functions:

The windings are supported by it.

It offers the magnetic flux a low-reluctance channel.

Breather

Silica gel makes up the transformer’s breather, which stops any ambient moisture from entering the transformer’s tank along with air. The dielectric oil will contract when the transformer’s temperature drops, which causes the transformer to breathe in ambient air. As a result, the silica gel of the breather absorbs all the moisture in the air.

Transformer Windings

The main winding and secondary winding are the two windings that make up the transformer. The transformer’s winding to which the load is attached is known as the secondary winding, whereas the winding linked to the AC supply source is referred to as the primary winding. The primary winding receives the application of the AC voltage V1 whose magnitude is to be adjusted.

Transformer Body / Tank and Dielectric Oil

The transformer’s core and windings are safeguarded by the transformer tank. The transformer’s windings and core are submerged in a tank of dielectric oil. The dielectric oil, also known as insulating oil, cools the transformer by absorbing heat while serving as an insulating medium for the core and windings of the transformer.

Oil Conservator Tank

Through a hose, a tiny tank known as the conservator tank is linked to the transformer’s main tank. The conservator tank’s primary job is to ensure that the transformer tank is always fully filled with dielectric oil. Transformer oil is intended to be stored in the conservator tank.

Transformer Components and Design

A transformer’s three primary components are:

- Transformer’s Primary Winding

- Transformer Magnetic Core

- Transformer Secondary Winding

Transformer’s Primary Winding

When coupled to an electrical source, it generates magnetic flux.

Transformer Secondary Winding

The flux generated by the main winding will flow through the core and connect with the secondary winding. This winding is likewise wound on the same core and provides the transformer’s required output.

Transformer Magnetic Core

The magnetic flux generated by the main winding will flow via this low reluctance channel coupled with the secondary winding to form a closed magnetic circuit.

Transformer are all classified as follows:

Depending on Voltage Levels

The most common transformer type, grouped according to voltage:

- Step-up Transformers are used to connect the power generator to the electricity grid. The secondary output voltage exceeds the input voltage.

- Step-Down Transformers are used to convert high voltage primary supplies to low voltage secondary outputs.

Depending on the Primary Methodology

We may expect to see a variety of core kinds in a transformer.

- Air core Transformer : The air serves as the conduit for the flux between the main and secondary windings. the windings or coils wrapped on the magnetically inert strip.

- Iron core transformer: Windings are coiled on several iron plates that are layered on top of each other, creating the ideal linking path to produce flux.

Depending on the types of cores

Core Type and Shell Type are the two main core kinds found in transformers. The way the primary and secondary coils are arranged around the steel core makes these two kinds different from one another.

- Core Type – In this type, the laminated core is encircled by the windings.

- Shell Type : In this type, the laminated core encircles the windings.

Depending on the installation location

- Power Transformer :Because they are appropriate for high voltage applications, power transformers are employed at power producing facilities.

- Measurement Transformer :These are further categorized as measurement transformers. They primarily measure voltage, current, and power.

- Potential Transformer :A well planned, incredibly precise step-down transformer is a potential transformer. It is typically used in conjunction with a 120-volt voltmeter. The user can calculate the voltage on the high side by multiplying the reading on the voltmeter (known as the deflections) by the transformation ratio. 10:1, 20:1, 40:1, 80:1, 100:1, 120:1, and even greater transformation ratios are frequently used.

- Current Transformer :A primary coil comprising one or more turns of heavy wire is present in a current transformer. It is always wired in series in the circuit being used to measure current. Numerous twists of tiny wire make up the secondary coil, which is always linked across the ammeter terminals. A current transformer’s secondary must never be open-circuited.

- Auto Transformer A unique kind of power transformer is the autotransformer. It is made up of one continuous winding that is tapped on one side to produce a step-up or step-down function.

- Protection Transformer :Transformers for component protection are known as protection transformers. Some components in circuits need to be safeguarded from voltage variations and other things. Component protection is provided by protection transformers.

- Isolator Transformer A highly special type of transformer is an isolation transformer. It features a 1:1 ratio of turns. As a result, voltage is not stepped up or down. Instead, it acts as a security measure. It is employed to separate a power line’s grounded conductor from the chassis or any other area of the circuit load. If contact is established across the transformer’s secondary winding, using an isolation transformer has no protective effect against hazard or shock.

- Distribution Transformer: Typically used for residential uses at distribution lanes. They are made to transport low voltages. It has low magnetic losses and is extremely simple to install.